What DOT Really Means: Brake Hose Inspection And Replacement

- Home

- Blog

- What DOT Really Means: Brake Hose Inspection And Replacement

Brake hoses are the most government-regulated components on a vehicle. Anyone making brake assemblies must be registered with the Department of Transportation (DOT). All aftermarket hose, fittings and complete hoses must conform to FMVSS 106 and SAE J1401. These tests are demanding and often exceed what a vehicle will see in the real world.

The DOT standard in a nutshell says brake hoses must be flexible in a wide range of temperatures while having a predictable expansion rate so the pedal feel and ABS response is the same in winter and summer. It also specifies that hoses must be able to bend and twist at certain angles without collapsing, kinking or bursting.

FMVSS 106 and SAE J1401 do not specify construction or materials. These documents outline a test procedure that completed hose must pass.

These tests and standards include:

• Markings: Each hydraulic brake hose, except the original hoses, have at least two clearly identifiable stripes of at least 1/16th of an inch in width, placed on opposite sides of the brake hose parallel to its longitudinal axis. These are called “torque stripes.” One stripe may be interrupted by the information printed on the hose. These are to prevent twisting during assembly and installation.

• Burst Pressures: The hydraulic brake hose assembly must withstand water pressure of 4,000 psi for two minutes without rupture. Hose that is 1/8 inch, 3 mm, or smaller in diameter must be tested at 7,000 psi.

• Whip Testing: Brake hoses are continuously bent on a flexing machine for 35 hours at pressure.

• Tensile Strength: A hydraulic brake hose assembly must withstand a pull of 325 pounds without separation of the hose from its end fittings during a slow pull test, and shall withstand a pull of 370 pounds without separation of the hose from its end fittings during a fast pull test.

• Cold Resistance: A brake hose is chilled to a temperature below minus 49º F for 70 hours shall not show cracks visible without magnification when bent around a cylinder.

• Chemical Resistance: In order to test the hose’s chemical resistance to brake fluid, the hose is subjected to a temperature of 248 degrees Fahrenheit for 70 hours while filled with SAE “Compatibility Fluid.” After this the hose is subjected to a 4,000 psi burst test.

• Ozone Resistance: A brake hose assembly is exposed to ozone for 70 hours at 104° F. Any cracks seen at a specific magnification is ground for failure.

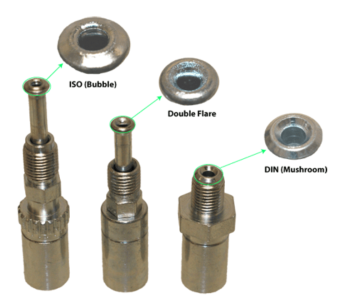

• Fitting Corrosion Resistance: After 24 hours of exposure to salt spray, a hydraulic brake hose end fitting must show no base metal corrosion on the end fitting surface except where crimping or the application of labeling information has caused displacement of the protective coating. What FMVSS 106 does not test for is damage that can take place over a longer period than 35 or 70 hours. It also does not take into account “acts of God” like impacts with road debris and installation errors.

There is not a recommended replacement interval for brake hoses. Brake hose conditions differ from vehicle, drivers and the environment. Inspection is the only way to spot a problem before a brake failure.

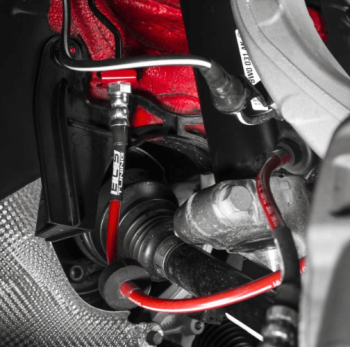

Brake hoses should be inspected visually and with your hands. It might be helpful to have someone pump the brake pedal to spot a defective brake hose. Failure typically occurs at the ends of the hose. This is where a hose flexes due to suspension/steering movement. It is also exposed to damage from debris and heat from the brakes.

If any of these signs are present, replace the hose:

- Cracks: Try flexing the hose to expose cracks. No matter how small, shallow or random the crack, the hose should be replaced.

- Blisters or Bubbles: Having someone pump the pedal will help spot this type of damage. The hose should not change shape. If even the smallest deformation is detected, replace the hose.

- Leaks or Stains: Brake hoses should never leak. A leak is lost braking force and an entry point for air and moisture. Air in the fluid is bad because air is compressible. This increases the amount of pedal travel that’s necessary to apply the brakes, and may increase it to the point where the pedal hits the floor before the brakes apply.

- Physical Damage: Run your fingers a long the length of the hose. A brake hose should be free of any irregularities.

- Corrosion on the Fitting: Most fittings are plated to prevent corrosion. If this plating wears away, corrosion can occur at an accelerated rate.

- Corrosion on Brackets and Mounting Hardware: Rust on the brackets can constrict a hose.

The Future

What is in the future for brake hoses? With efficiency of the engine becoming more important, the efficiency of the vacuum brake booster is coming into question. Engineers see the vacuum brake booster as a vacuum leak that can make the engine run rich or lean.

Without a booster, the transfer of force from the pedal to the caliper has to become more efficient. This could mean even stiffer and maybe smaller diameter brake hoses in the future.

10 Brake Hose Recommendations

- If the brakes have undergone extreme thermal shock, replace the hose.

- Always make sure the angle of the banjo fitting is correct.

- Use a torque wrench on banjo fittings.

- Always use new copper washers.

- If a caliper is sold, recommend a new brake hose.

- Never let a caliper dangle by the hose.

- If you plan to clamp a hose to push the piston back or for diagnostic procedures, clamp the hose in the middle, not near the ends or where it curves.

- If a replacement hose is not marked with the proper DOT and/or SAE mandated marking that include the date, manufacturer name and the letters “DOT,” send it back.

- If a hose on a vehicle does not have a torque stripe or other markings, it might be the original hose. Inspect it more carefully for damage.

- Don’t twist the hose. All replacement brake lines have a “torque stripe” or labeling information that should be straight when the hose is installed.